The world is faced with one of the biggest challenges it has ever had – the need to urgently remove around 1300 gigatons of historically built emissions in the atmosphere and transition to a net zero economy. Replacing fossil fuel energy generation with renewables and hydrogen energy seems like the ideal solution, however, it will take decades for the infrastructure and power capacities to be made available worldwide. While the world is transitioning towards clean energies, carbon capture technologies could facilitate the process and take their key role in reducing the flow of current emissions.

What is Carbon Capture and Storage?

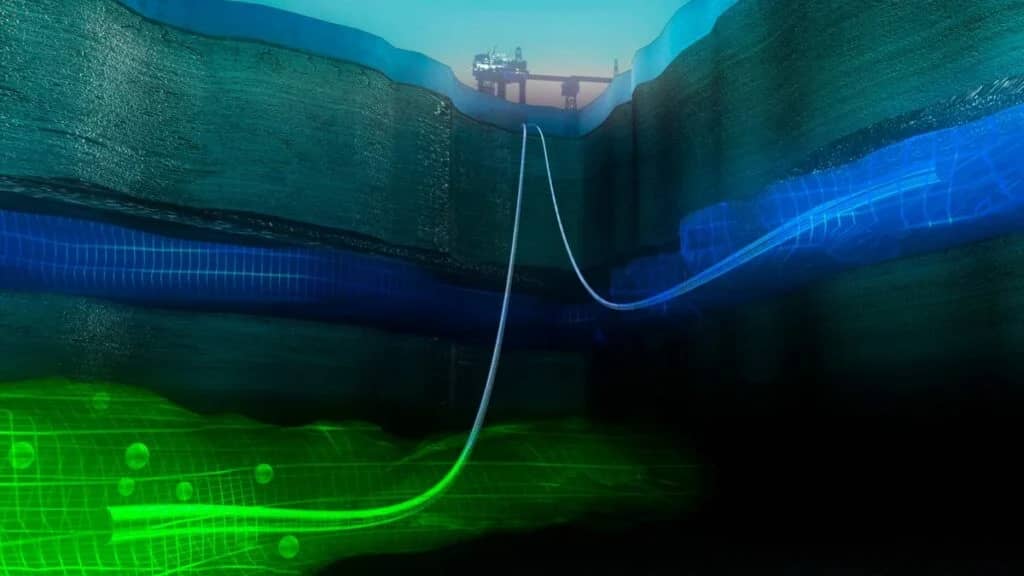

Carbon Capture and Storage (CCS) is a way of reducing carbon emissions, which could be key to helping to tackle global warming. It’s a three-step process, involving: capturing the carbon dioxide produced by power generation or industrial activity, such as steel or cement making; transporting it; and then storing it deep underground. Here we look at the potential benefits of CCS and how it works.

What is CCS?

CCS involves the capture of carbon dioxide (CO2) emissions from industrial processes, such as steel and cement production, or from the burning of fossil fuels in power generation. This carbon is then transported from where it was produced, via ship or in a pipeline, and stored deep underground in geological formations.

“It is great to take the next step towards a carbon-neutral future together with the rest of Africa.Gastec Group of Companies is pioneering solutions towards a clean and green climate for all.

Decarbonisation can only be achieved on a collective scale with AU and ECOWAS Communities, with integrated value chains and large-scale CO2 removal solutions. Gastec Group of Companies is taking a significant step, not only for the realization of carbon-neutral African Energy Economies to come in full scale like EU and the rest of the World.

“We are very proud to become a pioneer in the field of industrial CO2 circular economy in Africa together with our technical partners. With this next step, we aim to extend our decarbonisation solutions portfolio and make carbon capture and storage available to customers in Africa & Carribeans. For our industrial customers, in particular, CCS technology will play a key role in achieving their net-zero targets. As a partner to our customers, we stand ready to shape this path”,

Statement

Kingsley Jackson

Group CEO

Gastec Group of Companies

We develop and deploy direct air capture machines that remove CO2 from the atmosphere

Decarbonize the atmosphere with direct air capture technology. Engineered carbon removal for a net-zero future

Proven benefits: Increased profit.

We help the industry decarbonize and leverage the growing value of captured carbon. The opportunity to take part in the circular economy of capturing and selling carbon dioxide is predicted to be a key differentiator for long-term success. It’s the first movers that will stand to benefit the most.

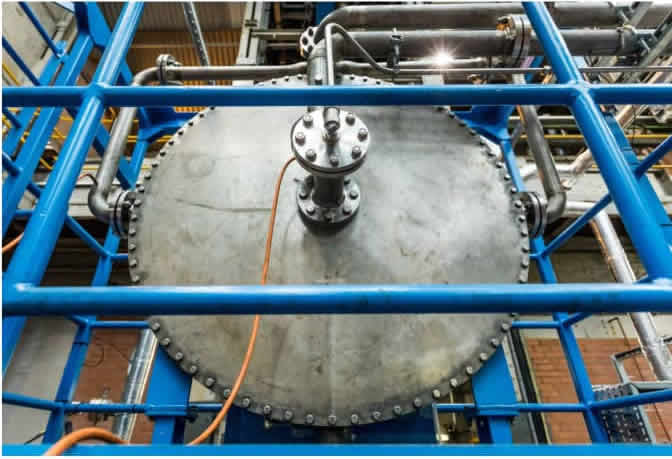

MODULAR SYSTEMS

Facilities ready to harness the benefits of modularisation today, we offer semi-modular solutions

These systems modularise and containerise about 80% of a carbon capture system, giving you the majority of the benefits of modularisation. Installation and on-site activity is dramatically reduced compared to an open-plant construction.

Our semi-modular systems are proven, fully scalable solutions, currently being operated

Industries We Serve

Refineries

Cement

Steel

Energy from Waste

Biogas

The refining sector faces increasing pressure to lower carbon emissions as net zero initiatives become more widely adopted. This will only increase over the coming decades. Carbon capture and storage technology provides one of the best ways refineries can decarbonise, and can be paired with hydrogen production to provide new opportunities and diversify value chains.

The cement sector is the largest industrial carbon emitter in the world. With our CO2 capture technology, 90%+ of these emissions can be captured, utilised or stored.

Cement is the world’s leading construction material — but it’s also one of the key drivers of climate change, responsible for around 8% of global CO2 emissions. Carbon capture is a vital technology to decarbonise cement manufacture, as up to 70% of CO2 emissions come from the chemical process of calcining calcium carbonate—which can’t be achieved with other methods.

Our carbon capture technology is already being deployed by leading cement companies. It offers the sector an achievable and proven means of decarbonising, that is available now.

Steel industry challenges

The steel industry is one of the largest industrial sources of CO2 emissions, and production continues to grow. As the world moves to achieve net zero targets, decarbonising steel production will remain a key area to be addressed.

Many facilities have limited options for reducing emissions through improved energy efficiency and a reduction in coal consumption. To achieve a significant reduction in CO2 emissions, the implementation of carbon capture and storage technology is required

Energy from Waste industry challenges

The Energy from Waste (EfW) industry helps make urban living sustainable by transforming growing waste generation to power generation. However, the process results in net CO2 emissions that are harmful to our planet. With carbon capture and storage at EfW plants, municipalities can move towards negative carbon emissions whilst simultaneously handling waste and producing power.